Type |

Feature |

Dimensional Accuracy |

Unit Weight |

Quantity of Production |

Deform of Parts |

Cost |

Investment Casting |

| * |

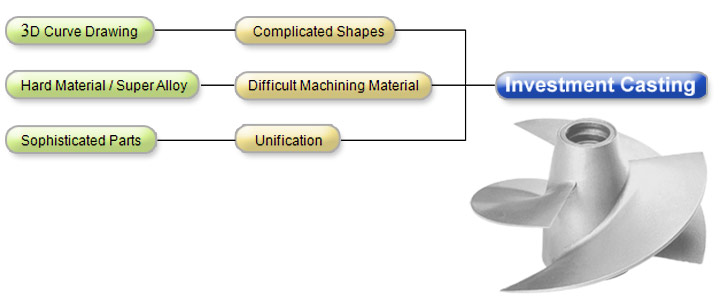

Sophisticated construction parts. |

| * |

Suitable for difficult machining or forging parts |

| * |

Applicable for special alloy, such as Ti, Al. |

|

±1%

(also ±0.5%) |

Free

(Normally≦30Kg) |

≧500 |

◎ |

○ |

Machining |

| * |

High precision parts. |

| * |

Flexible production quantity, especially low quantity. |

|

±0.01 |

Free |

≧1 |

X |

X |

Metal Injection Mold |

| * |

Tiny, light & sophisticated parts. |

| * |

Suitable for difficult machining parts. |

| * |

Suitable for mass production parts below 20g. |

|

±0.1 |

Light

(Normally≦20Kg) |

≧1,000 |

○ |

△ |

Sand Casting |

* |

High flexible production. |

* |

Quick production run. |

* |

Applicable for low quantity, high variety or mass production. |

* |

Surface roughness is not strictly required. |

|

±2 |

200Kg |

≧1 |

○ |

○ |

Hot Forging |

* |

Increasing strength & toughness of parts. |

* |

High & reliable production. |

* |

Suitable for various metal material. |

* |

Weight of parts depend on equipment. |

|

±0.3 |

Depends on forging equipment |

≧25,000 |

△ |

◎ |

Cold Forging |

* |

Suitable for small parts with mass production. |

* |

Low material lost, high efficiency productivity. |

* |

Applicable for simple shape & precision parts. |

|

±0.05 |

Light

(Normally≦10Kg) |

≧50,000 |

△ |

◎ |